UV coating system for VHB tape

Widely used in: film, tape, coating industry, hot melt adhesive UV coating, automotive wire harness tape, PVC wire harness tape, cloth tape, double-sided tape, industrial tape, pressure-sensitive adhesive tape, medical tape, silicone release film, decorative film, skin-feel film, optical film, hardened film, anti-peep film, polarizer, quantum dot film, texture film, car film, solar film, glass film, release film, waterproof film, protective film, scratch-resistant film, touch film, protective film, aluminum foil film, OCA optical film, VHB industrial tape, car clothing film, transfer film, explosion-proof film, acrylic, PC board, frosted process, PET, PETG, PVC, PC, PE, POBB, OPP, new energy, solar energy, lithium battery, photovoltaic, glasses and other special UV industries…

Category:

Keywords:

Qingda

Share to:

Detailed introduction

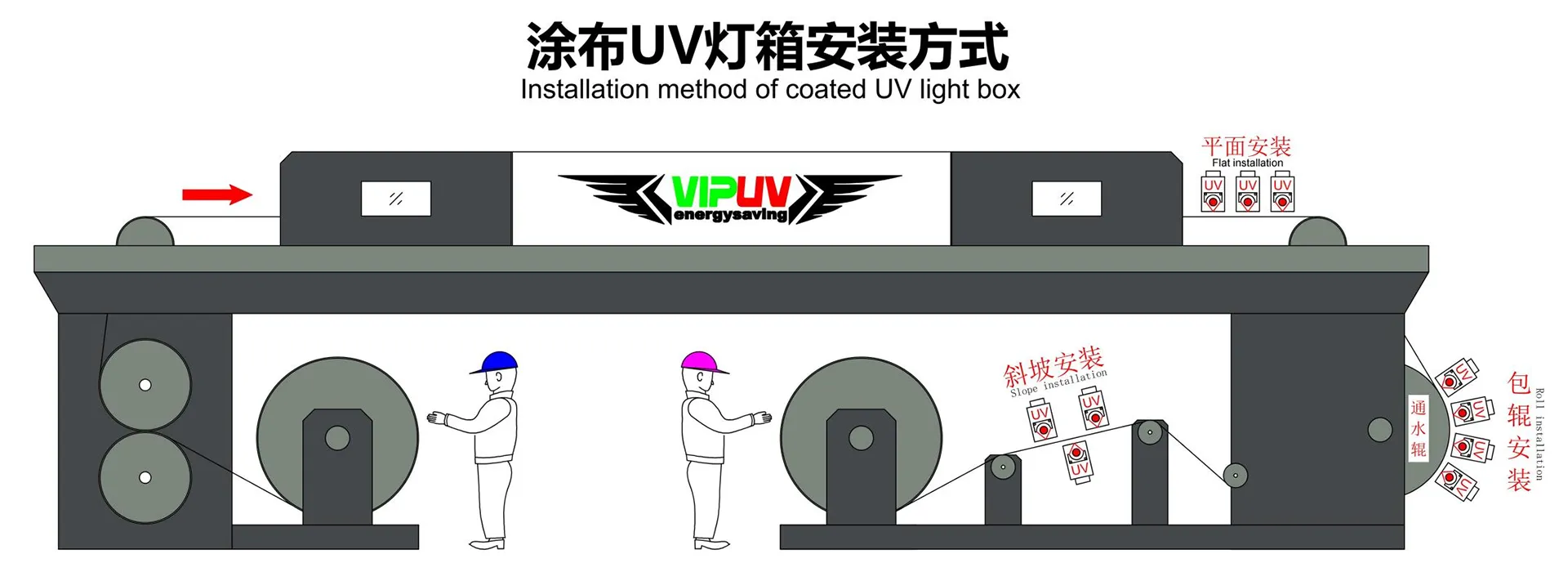

Coating machine production speed: 1-300m/min (Production speed can be customized according to customer's actual needs)

Maximum film width: 300mm~3000mm (Can be customized according to customer's actual needs)

UV band: 250nm~450nm (Common UVA, UVB, UVC, UVV, can be customized according to customer needs)

UV intensity: 100mw/c㎡~1000mw/c㎡ (Can be customized according to customer needs)

UV energy: 100mj/c㎡~100000mj/c㎡ (Can be customized according to customer needs)

Number of UV lamps: 1~6 UV lamps (Can be customized according to customer needs)

Application areas:

Widely used in: films, tapes, coating industry, hot melt adhesive UV coating, automotive wire harness tapes, PVC wire harness tapes, cloth tapes, double-sided tapes, industrial tapes, pressure-sensitive adhesive tapes, medical tapes, silicone release films, decorative films, skin-touch films, optical films, hardened films, anti-peep films, polarizers, quantum dot films, textured films, automotive films, solar films, glass films, release films, waterproof films, protective films, scratch-resistant films, touch films, protective films, aluminum foil films, OCA optical films, VHB industrial tapes, car clothing films, transfer films, explosion-proof films, acrylic, PC boards, frosted processes, PET, PETG, PVC, PC, PE, POBB, OPP, new energy, solar energy, lithium batteries, photovoltaics, glasses and other special UV industries...

Previous page

Next page

Previous page

Next page

Intelligent Control System

Human-Machine Interface

Chinese display, touchscreen operation

Light tube switch

Each UV lamp tube is independently controlled.

Power adjustable

10% to 100% continuously adjustable

Smart Whimsicality

Automatically adjusts airflow based on UV lamp power

Energy Monitoring

Online energy monitoring, automatic energy closed-loop control, and optional energy auto-compensation

Nitrogen protection

Nitrogen-protected, oxygen-free UV curing system (custom-designed to meet your specific needs)

Fault output

Capable of online control, turning off the lights, and stopping the coating machine from operating.

Fault Alarm

Over 20 protection features including overtemperature, overvoltage, overcurrent, overheating, phase loss, open circuit, and short circuit, among others.

Certificate of Honor

A national high-tech enterprise, the company has been honored as a "CCTV Exhibition Brand" and is a successfully listed company in the UV industry.

Core Advantages

UV curing industry's successful "listed company" and National High-Tech Enterprise

Quality

Low temperature, high energy, long lifespan, high efficiency, no need to add water, leak-proof, clog-free, non-deformable, low failure rate, easy maintenance. UV energy is monitored automatically online (with an automatic closed-loop UV energy system and energy auto-compensation, preventing defective products and avoiding losses).

Qualifications

A successfully listed company in the UV industry and a National High-Tech Enterprise.

Vision

Becoming a globally recognized VIPUV brand in the UV light-curing equipment industry.

Mission

Consistently delivering value to customers, reducing costs, and enhancing efficiency.

Company Strength

I want to leave a message.

I WANT TO LEAVE A MESSAGE